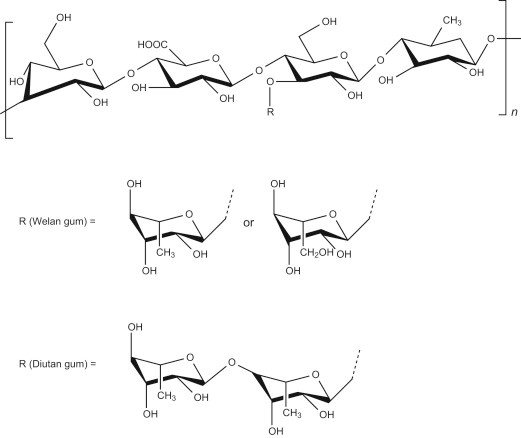

Welan gum and Diutan gum

Welan gum and diutan gum both are high-molecular-weight microbial polysaccharides produced by aerobic fermentation. They both belong to the sphingans group.

Welan gum is synthesized by the fermentation process of the Alcaligenes sp. ATCC 3155. It contains a tetrasaccharide backbone chain with l-mannose, l-rhamnose, d-glucose and d-glucuronic acid. The side chains contain a single unit of either l-mannose or l-rhamnose substituted in C3 of every 1,4-linked glucose molecule. This polysaccharide has an approximate molecular weight of 106 g/mol.

Diutan gum has a similar structure to welan gum, but the side chains of the former consist of two units of l-rhamnose. In addition, diutan gum has a molecular weight up to three times higher than welan gum, of about 3–5 × 106 g/mol .

The structure of both polysaccharides. The presence of d-glucuronic acid in both gums gives them anionic charges and the ability to adsorb onto the surface of cement particles. Welan and diutan gum exhibit good rheological properties and are stable at extreme temperature and pH. In aqueous solution, both gums adopt a double-helical conformation where the side chains screen the carboxylate groups of the backbone and prevent cross-linking by calcium ions. The shielding might be higher in the case of diutan gum due to its longer side chains compared to welan gum. This screening gives both gums high stability in media with high Ca2+ concentrations, as in cement pore solutions. With all these properties, welan and diutan gums are suitable VMAs for application in cementitious systems.

The chain structure of diutan gum is different from welan gum. Diutan gum has two rhamnose side chains compared to welan gum that had only one rhamnose and one mannose. The molecular length of diutan gum is up to three times more than that of welan gum, and its molecualr mass is higher.

Diutan gum is a natural high-molecular-weight gum produced by carefully controlled aerobic fermentation. The repeating unit is composed of a six-sugar unit. The backbone is made up of d-glucose, d-glucuronic acid, d-glucose, and l-rhamnose, and the side chain of two l-rhamnose. When added to cement grouts, diutan gum exhibits a shear-thinning behavior compared to a control grout without VEA. At low shear rates, the grout showed a high apparent viscosity, that resulted from entanglement and interwining of the polymer, whereas at HSR (high-shear-rate) the viscosity decreases because of the alignment of the polymer along the direction of the flow, thus enhancing fluidity. Compared to welan gum, it was observed that diutan gum is more shear thinning and exhibited higher viscosity at low shear rates at the same dosages of VEA and superplasticizer. This difference is attributed to the higher-molecular-weight and longer chain of the diutan gum. It is also known that the viscosity of diutan gum is higher under alkaline environment and in the presence of calcium ions, such as that found in fresh cement paste.

At early ages, the diutan gum showed a set retarding behavior and reduced strength of the cement pastes, compared to the control. With respect to the effects of diutan gum on cement hydration, samples of cement paste studied by thermal analysis have shown that the addition of diutan gum causes a higher content of calcium hydroxide compared to control cement paste. This indicates a higher degree of hydration promoted by the adsorption of water molecules on the surface of cement particles. However, the compressive strength was lower in cement pastes containing diutan gum compared to the control.